As a kid I loved the idea of making things. I joined woodshop in 2012, the starting year of middle school, and until I left that school in 2014 I kept making things. I eventually branched off during this time into programming, which persists to this day, but something has always been on the back of my mind: I want to make a quadcopter.

Now, I have no formal education in electronics. I am a computer science major, and have only ever touched code. My uncle has tried to get me to work with him on projects, but I was too burned out to ever get properly involved; my brain has been wanting to start something though.

This feeling has finally broke. My 2024 tax return came in, and; for whatever reason; I decided to start. I spent $500 in tools and materials, and as it was in transit I realised I need to make a space for it. My little office has no more wall space, and there are no rooms for me to take over. Looking around my office, the only unused space is near my desk; but there is a radiator there. It would be a perfect spot for the workspace, and for this reason I took my knowledge from 2013 and went to work.

I haven't done any carpentry in years, only barely touching tools and Ikea furniture; but like riding a

bike the skills flooded back. I made this little leaning table, and it fit my things perfectly!

Now that I have my workbench, I need something to make. Although I am in progress of designing the quadcopter circuit, I'm not too confident in my abilities yet. Because of this I started with a smaller project: a simple fan circuit with an LED indicator light.

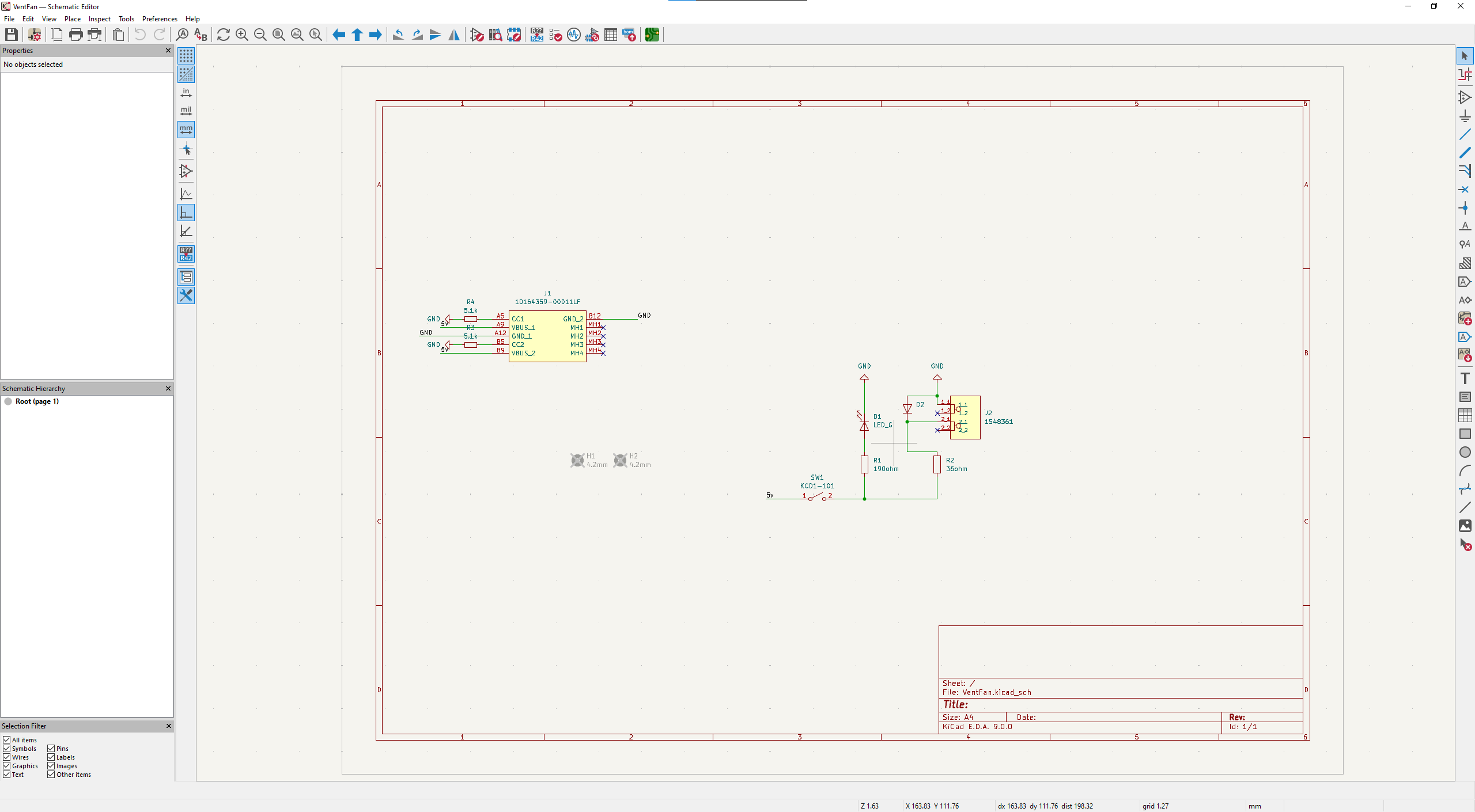

This tiny project helped me learn a tonne. I started with the schematics: I have never touched a CAD

software before, and KiCAD was my first. Learning the tool was quick enough, and after figuring out how

to draw my schematic, I had my first circuit.

I learned all about the passive components through this. Although it has no IC, figuring out how to hook in wall power via USB-C was exciting. From this I managed to be confident in knowing how ICs wire up, and feel like I can actually put them together without breaking the components.

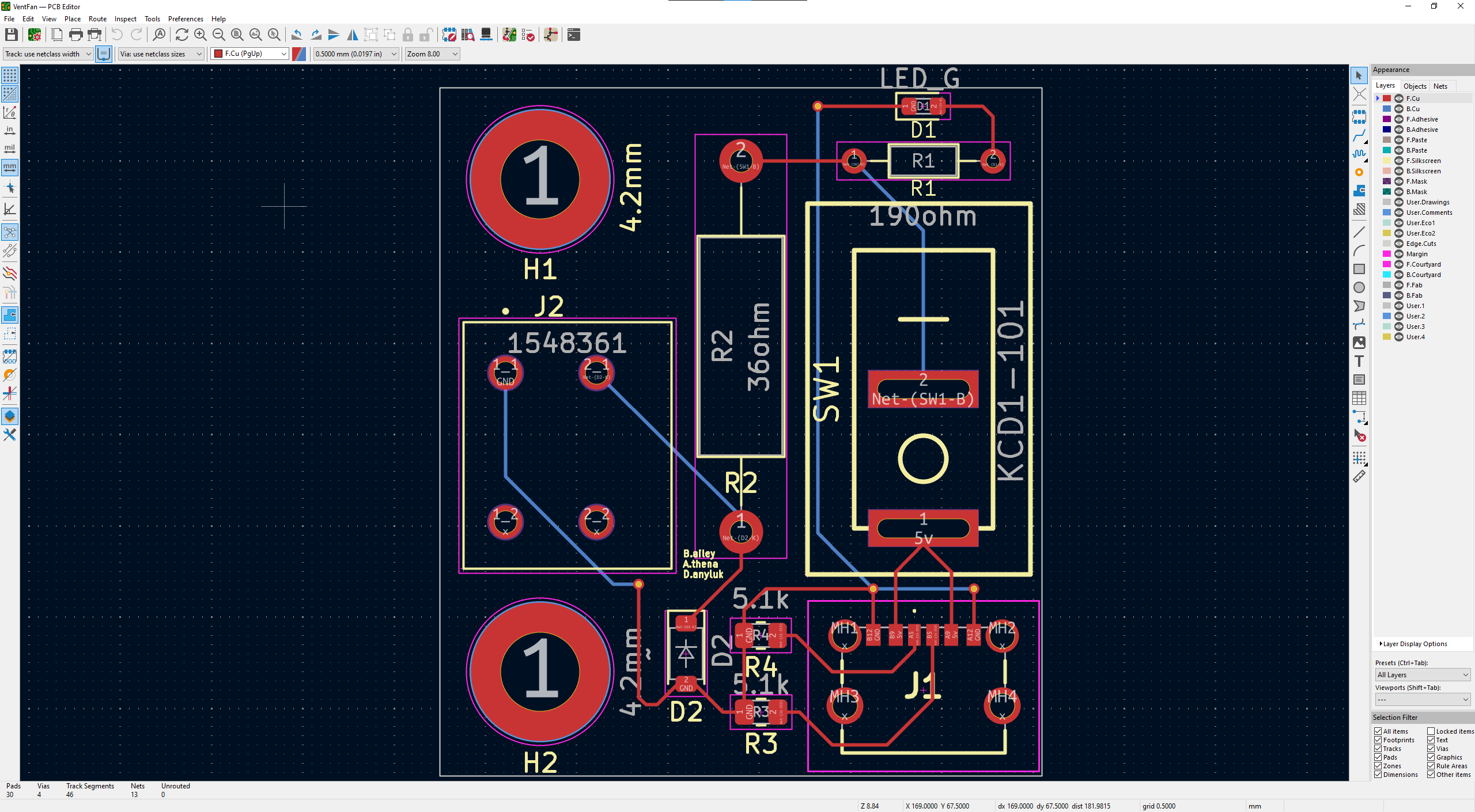

Next was PCB design, and it was simpler than expected. I read anecdotes before from Reddit and Hackernews

users about putting the mounting holes first, and I listened sagely. I knew what components I had ordered

and learned all about the standard sizing from this, with both surface mounted and throughhole components

sprinkled on. I ended up with this little 3.0x3.5cm board, and I am impressed with my ability to make it

this compact right away.

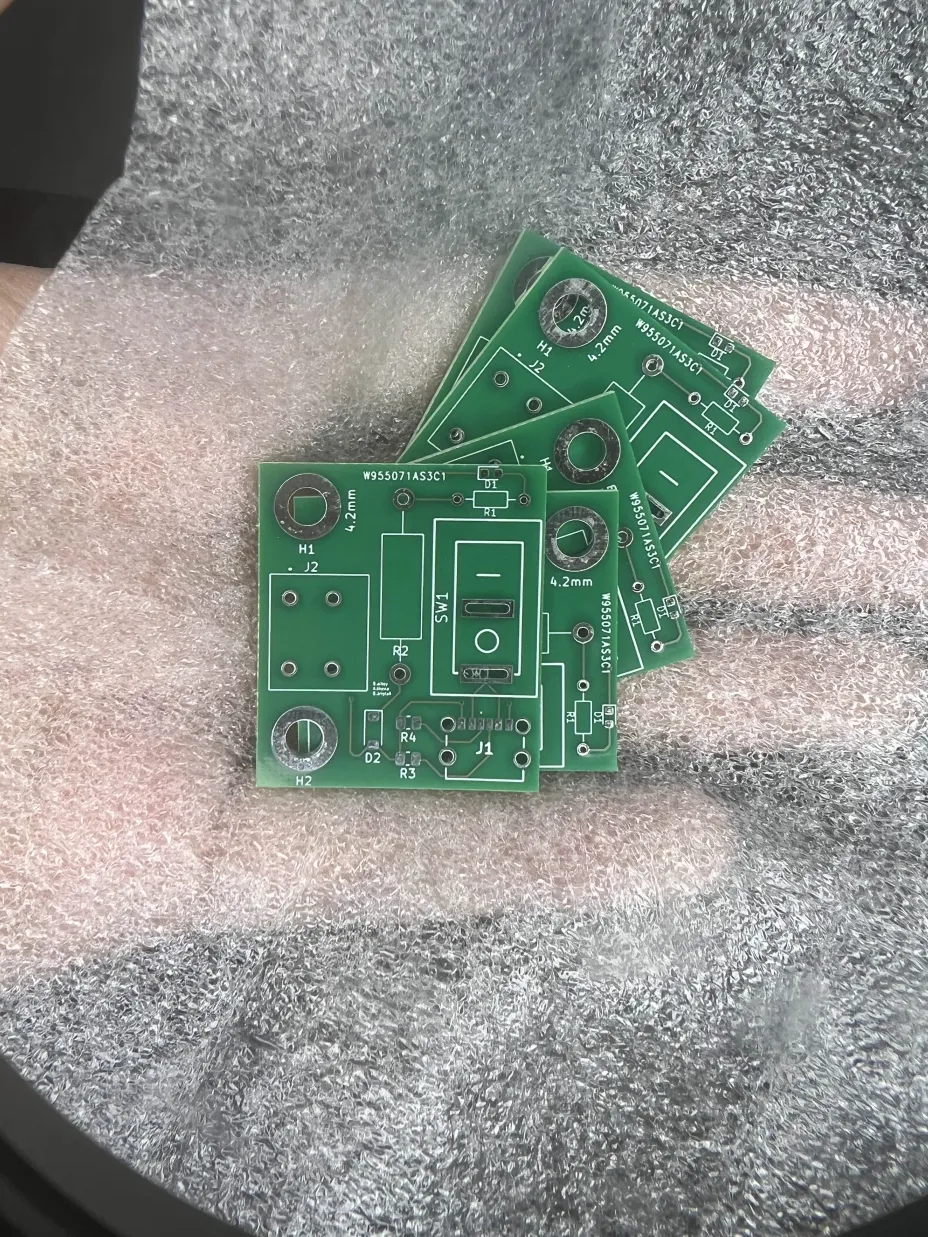

I ordered the board from PCBway, messed up giving them my files, and waited tenatiously for the board to

arrive. And was it ever like Christmas when it did. I was so excited to get started. I showed my girlfriend

the board, she put it in her mouth, spit it out when I told her it could be toxic; all of the good things.

And then I got to work.

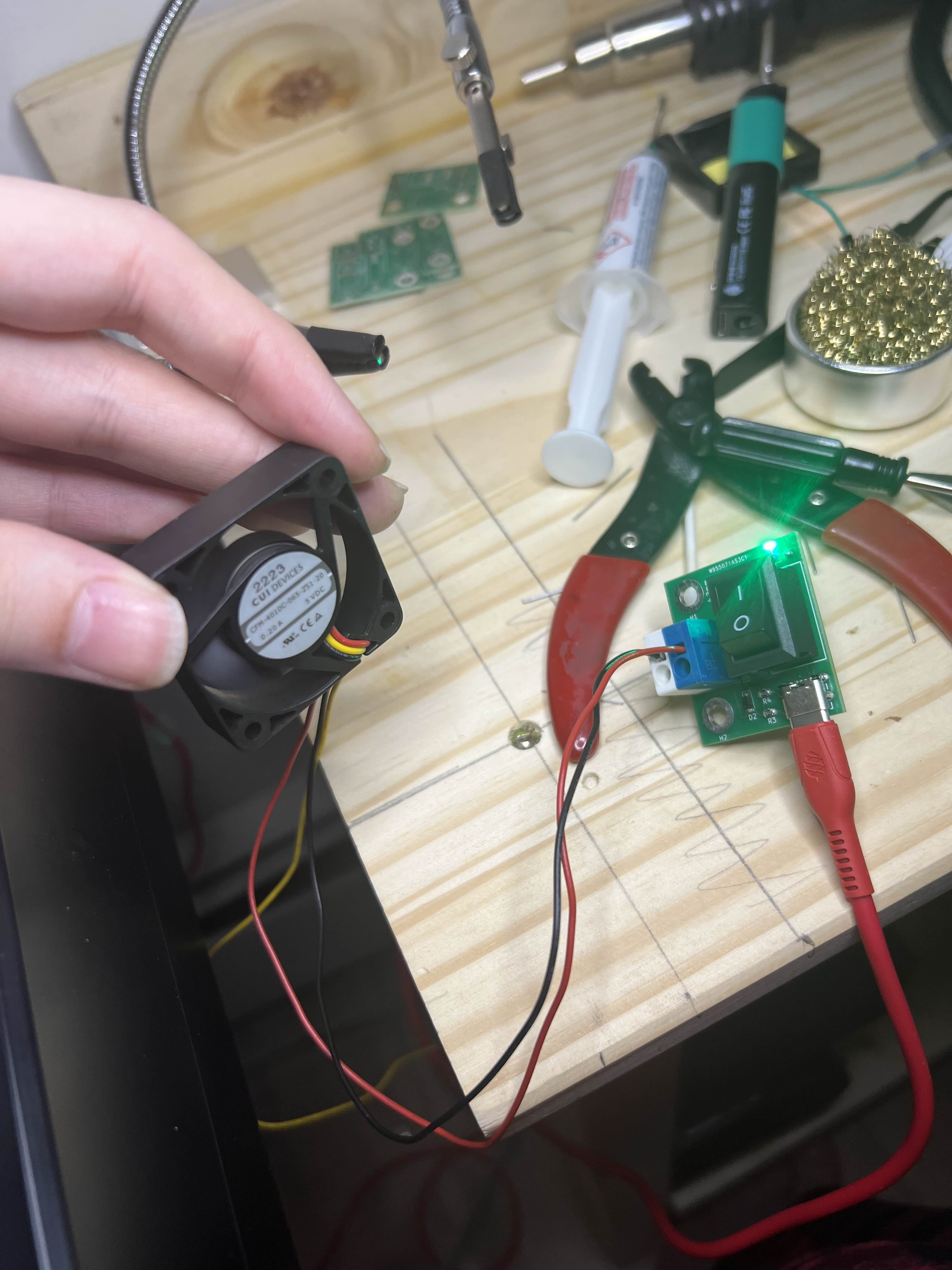

My first board got burned from me using too low of a temperature with the solder paste: I didn't realise that

lead-free solder would have such a higher melting temperature; I didn't learn this until after I mounted the

LED on the second board. Once I did, seeing the resistors and diodes just find themselves to their pads was

enthralling. I was worried that I'd fuck it up somehow and waste a lot of parts, and although I did because

I kept dropping the tiny SMD components, I ended up with something working.

This was a fun first step into the world of electronics. It was a very simple start to it, and I think that it was worth it: I have learned so much from this fan controller that I was worried would take ages to get a grasp on. But my first PCB has been made, and hopefully many more will follow. As I journey towards my quadcopter, I hope this documentation shows that getting into electronics isn't that hard, and I am looking forward to documenting the process.